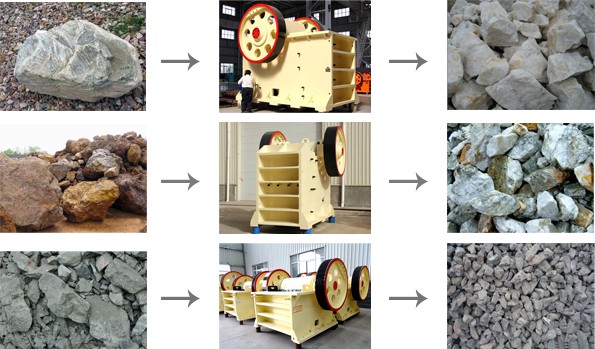

Jaw crusher for sale is mainly used for the primary crushing of various of ores and large materials. A single jaw crusher machine can produce up to 1000 tons per hour. The raw materials it can crusher include quartz stone, bluestone, river pebbles, pebbles, limestone, iron ore, and so on. Moreover, it is widely used in mining, smelting, building materials, highway, railway, water conservancy, chemical and other industries. Due to its high working efficiency and reliable performance, the jaw crusher plant is the hot sale product. In addition, for a complete of crushing production line, a jaw crusher equipment is also a crucial component. Welcome to contact us if you are interested in it.

Types and specifications

The jaw crusher has many different types in order to meet the demand of different customers. According to its mobility, the jaw crusher mini includes stationary type and mobile type. Usually, the stationary type jaw crusher plants are popular. And it usually works for the crushing production line. In addition, for those projects with shorter period of time and greater mobility, the mobile jaw crushers are a better choice.

Meanwhile, according to its structural characteristics, it includes double toggle jaw crusher and single toggle jaw crusher.

When you choose the suitable specification of jaw rock crusher, you should consider the following aspects, including the size of the feeding port, the capacity of the crusher to process raw materials per hour, the motor power, etc. The jaw crusher model is named according to the size of the feed inlet.

So when you want to buy a right jaw machine, you need to only only select a right type, but also the right specification. If you don’t know how to buy a good machine, welcome to consult us now!

| Model | PE150×250 |

| Size of Feed Opening (mm) | 150×250 |

| Max. Feeding Size (mm) | 125 |

| Adjustable Size of Discharge Opening (mm) | 10-40 |

| Capacity (t/h) | 1-3 |

| Power (kw) | 5.5 |

| Model | PE150×750 |

| Size of Feed Opening (mm) | 150×750 |

| Max. Feeding Size (mm) | 125 |

| Adjustable Size of Discharge Opening (mm) | 18-48 |

| Capacity (t/h) | 8-25 |

| Power (kw) | 15 |

| Model | PE250×400 |

| Size of Feed Opening (mm) | 250×400 |

| Max. Feeding Size (mm) | 210 |

| Adjustable Size of Discharge Opening (mm) | 20-60 |

| Capacity (t/h) | 5-20 |

| Power (kw) | 15 |

| Model | PE400×600 |

| Size of Feed Opening (mm) | 400×600 |

| Max. Feeding Size (mm) | 340 |

| Adjustable Size of Discharge Opening (mm) | 40-100 |

| Capacity (t/h) | 16-65 |

| Power (kw) | 30 |

Features of jaw crusher

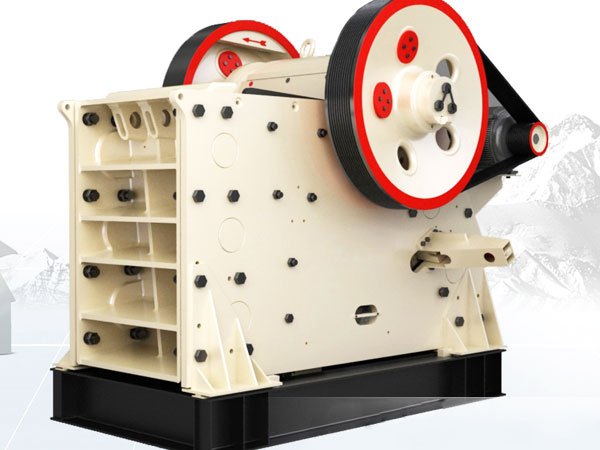

- Special structure, high yield and energy saving. Our jaw crusher for saledeepens the “V-shaped” deep cavity, high yield and energy saving. And our crushing no dead angle, the finished product particle size uniform.

- Advanced manufacturing technology, material selection of good quality. Our jaw crushersadopt advanced manufacturing technology and high abrasion resistant materials, which makes the whole equipment more durable.

- Reasonable design of feeding port, large productivity. The jaw crusher stoneis equipped with the new type of tooth guard plate, the effective area of jaw plate crushing increases, making the production capacity increase.

- The lubrication system is safe and reliable, the parts are easy to replace, and the equipment maintenance is simple.

- The discharge port is equipped with adjusting device, which makes the adjustment range large, increases the flexibility of the equipment, and can meet the requirements of different customers.

| Model | PE500×750 |

| Size of Feed Opening (mm) | 500×750 |

| Max. Feeding Size (mm) | 425 |

| Adjustable Size of Discharge Opening (mm) | 50-100 |

| Capacity (t/h) | 45-100 |

| Power (kw) | 55 |

| Model | PE600×900 |

| Size of Feed Opening (mm) | 600×900 |

| Max. Feeding Size (mm) | 500 |

| Adjustable Size of Discharge Opening (mm) | 65-160 |

| Capacity (t/h) | 60-160 |

| Power (kw) | 75 |

Jaw crusher diagram

Jaw crushers are typically defined by the opening size. For instance, the 900 X 650 mm jaw crusher is a crusher that has an inlet that measures 900 mm X 650 mm. The technical parameters and parts of the jaw crusher plants include the following: feed chute; V-belts; drive flywheel; electric motor; damping and settings group; motor stand; toggle plate; hydraulic cylinder; discharge; swing Jaw; fixed Jaw.

Jaw crushers and plants are most commonly designated by the top opening size where the materials enter. These openings are either square or rectangular and referred to in inches. When working, the jaw plant mainly relies on its moving and static jaw these two jaw plates.

Jaw crusher VS Cone crusher

The diesel jaw crusher and cone crusher are popular crusher machines. But they have many differences. Knowing their differences can help you choose a more suitable crusher machine.

First of all, in terms of volume, the double jaw crusher is small in size while the cone crusher is large in size.

Then, in terms of the types of materials to be processed, the jaw crusher is suitable for handling materials of different hardness, such as pebbles, granite, limestone, etc, while the cone crusher is more suitable for crushing hard materials.

Next, in the terms of the crushing stage, the feeding inlet of the jaw crusher for sale is large, suitable for primary crushing, also known as coarse crushing. In comparison, the feed inlet of the cone crusher is small, suitable for secondary crushing of materials, also known as fine crushing.

Finally, in terms of the scope of application, the jaw crusher has many specifications, which can be used in all kinds of sand factories. The cone crusher is suitable for large and medium-sized sand and gravel factories.

| Model | PE750×1060 |

| Size of Feed Opening (mm) | 750×1060 |

| Max. Feeding Size (mm) | 630 |

| Adjustable Size of Discharge Opening (mm) | 80-160 |

| Capacity (t/h) | 110-320 |

| Power (kw) | 110 |

| Model | PE800×1060 |

| Size of Feed Opening (mm) | 800×1060 |

| Max. Feeding Size (mm) | 640 |

| Adjustable Size of Discharge Opening (mm) | 130-190 |

| Capacity (t/h) | 130-330 |

| Power (kw) | 110 |

How dose a jaw crusher works?

The mobile jaw crusher for sale features a moving jaw and fixed jaw. The jaw that moves compacts the materials against the jaw that is fixed crushing the materials into smaller pieces. The crushed materials then leave the jaw through the bottom part of the crusher which is better known as a discharge opening. The discharge opening comes in different sizes which control the size of the products that the crusher produces.

The jaw mill machine is equipment that is primarily used at the beginning stages of reducing materials for a number of different applications. This includes gravel and sand, rock quarries, construction, mining, demolition recycling, metallurgy, chemical industries, and construction aggregates.

The flywheel, pitman, toggle plates, driving motor, and the eccentric shaft of the jaw crusher generate a crushing action. It also supplies the energy that is required to break down materials.

| Model | PE900×1200 |

| Size of Feed Opening (mm) | 900×1200 |

| Max. Feeding Size (mm) | 750 |

| Adjustable Size of Discharge Opening (mm) | 95-210 |

| Capacity (t/h) | 220-450 |

| Power (kw) | 132 |

| Model | PE1000×1200 |

| Size of Feed Opening (mm) | 1000×1200 |

| Max. Feeding Size (mm) | 850 |

| Adjustable Size of Discharge Opening (mm) | 200-300 |

| Capacity (t/h) | 280-560 |

| Power (kw) | 160 |

Pay more attention to the quick-wear parts

The quick-wear parts of the jaw crusher machine are the concern of many customers. These quick-wear parts have an effect on the service life of the jaw rock crusher. So regularly maintenance and changing the quick-wear parts are very important.

The quick-wear parts include the moving jaw plate, the fixed jaw plate, the toggle plate, bearings, the gaskets and so on. Some of these wear parts need to be replaced every four months, while others need to be replaced every six months or once a year. If you purchase our jaw stone crusher, our salesman will advise you to keep a few more sets of wearing parts before transportation. This way, when you need to replace wearing parts, you can replace them quickly and reduce downtime. Short downtime will save your jaw crusher cost.

After reading this article, if you want to learn more information about the jaw crusher for sale, or you are interested in it, welcome to leave your message to us! We will provide you 7*24 hours service. And we promise to offer you a favorable jaw crusher price!