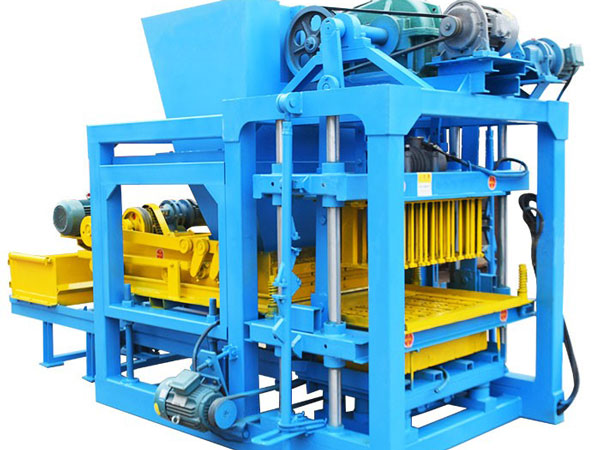

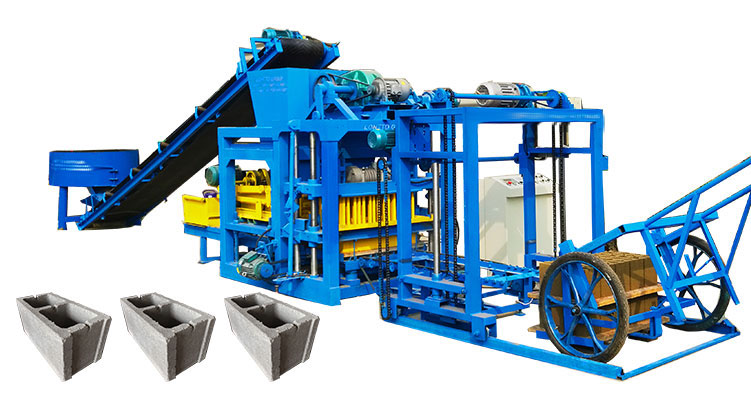

The concrete block machines for sale mainly can be used to produce the concrete bricks. It is a kind of brick machine without burning. The raw materials of concrete block making machine is various, such as cement, cinder, fly ash, construction waste, slag, stone powder, fine sand, industrial tailing, etc. Different from the raw materials of other type machinery, its raw materials are easy to get and its price is cheap, which can greatly save your original costs. Our BMM series of concrete block making machine for sale is hot sale on the market. Its specific specifications include BMM4-15, BMM5-15, BMM6-15, BMM8-15, BMM10-15 and BMM12-15. Choose a more suitable one for your business!

Characteristics of concrete block machine

- Produce different shape and sizes of bricks. As long as you change its molds, besides the concrete bricks, the concrete block making plantalso can produce the hollow blocks, solid blocks, interlocking bricks, paving bricks, etc.

- Different control systems of concrete block maker machinefor your selection. You can select suitable control system according to your needs, fully automatic type – PLC plus computer control, semi automatic type – cpanel control, and manual type.

- Low purchase cost and quick return. You don’t need too much money to invest in a concrete block manufacturing plant. Of course, if you have enough purchase costs, you also can invest in a concrete block production line. Moreover, the quick return of this concrete block moulding machine for salecan improve your return on investment.

- High quality and long service life. The main parts of our concrete block plant for saleadopts international famous brands. This can not only ensure the quality of our concrete block production plant, but also guarantee its service life. So you can get more benefits from your products.

| Model | BMM4-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 720-960 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 5930-6720 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4600 |

| Pallet Size(mm) | 1020×570 |

| Exciting Force(KN) | 55 |

| Overall Power(KW) | 27.5 |

| Model | BMM5-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 900-1200 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 7680-8800 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1100×570 |

| Exciting Force(KN) | 60 |

| Overall Power(KW) | 32 |

How to buy a right concrete block maker

Picking a right concrete block machines for sale is important when you want to start your business. Whether you want to need bricks for your projects or you want to selling the finished bricks, investing in a high-quality concrete brick making machine for sale is an ideal choice for you.

The first thing you should do is to think about the demand of concrete blocks. With a concrete block maker for sale, you have to make sure the number of blocks generated are in line with your output requirements. For example, some businesses aren’t going to need as many as they think, while others are going to scale rapidly.

This is going to depend on the project you are working on. You have to think about your options and then only go with a solution that’s worthwhile. Know the number of blocks produced by the concrete block laying machine, you need to evaluate whether it meets the needs of your project.

In addition, pay more attention to the stability and durability of the concrete brick making plant. Buy a perfect fully automatic concrete block making machine can increase its service life and increase its value.

| Model | BMM6-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1080-1440 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 7680-8861 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4500-5100 |

| Pallet Size(mm) | 900×700 |

| Exciting Force(KN) | 65 |

| Overall Power(KW) | 28 |

| Model | BMM8-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1200-1600 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 9000-10000 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 950×900 |

| Exciting Force(KN) | 85 |

| Overall Power(KW) | 51 |

Guarantee the quality of the finished bricks

When you plan to invest in a concrete block machines for sale, you all want to get high-quality bricks for your projects or selling them. So how to guarantee the quality of the finished bricks? How about the quality of concrete bricks produced by this concrete block maker machine for sale?

As we mentioned above, the premise of the matter is that you should buy a high-quality concrete block moulding machine. Then the quality of its raw materials is equally important. Before choosing the raw materials, you should inspect their quality carefully. Meanwhile, you should set the ratio of different raw materials in advance. The ratio depends on the different bricks produced by your concrete block plant.

What’s more, the operators of your concrete brick machine should be trained by professional engineers before using this machine. Correct operation ensures correct and efficient production. Good concrete blocks can guarantee the quality of your projects or you can sell these bricks for a higher price.

| Model | BMM10-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1440-1800 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 11011-12480 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1100×900 |

| Exciting Force(KN) | 110 |

| Overall Power(KW) | 67 |

| Model | BMM12-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1728-2160 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 12700-14400 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1300×900 |

| Exciting Force(KN) | 110 |

| Overall Power(KW) | 67 |

Concrete block making machine price list

Most of customers who want to invest in a concrete making machine all are concerned about its price. Yes, the price is something that is going to weigh on your mind. Going with something overpriced should never be an option even though it may seem like the right way to go. With so many quality hydraulic concrete block making machine on the market right now, why not choose something that is cost-efficient?

The concrete block machine price is affected by many factors, such as brands, types and models, its configurations, the concrete block making machine manufacturers, etc. It is necessary to take these factors into full consideration if you want to get a minimum concrete block making machine price.

If you feel that bothers you, there is a faster way to get a reasonable concrete block manufacturing machine price. That is to look for a trustworthy concrete block machine manufacturer. As long as you think your manufacturer is reliable, you will trust him to help you get a good concrete brick making machine price. In that case, you may consider our Daswell Machinery CO., LTD.

| Model | BMM4-40B |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 250-312 |

| Molding Cycle(s) | 240 |

| Vibration Frequency(rpm) | 2800 |

| Pallet Size(mm) | 850×450 |

| Exciting Force(KN) | 40 |

| Overall Power(KW) | 9.3 |

| Model | BMM4-26 |

| Capacity

(for 390×190×190mm hollow brick) (pcs/h) |

375-500 |

| Molding Cycle (s) | 26 |

| Vibration Frequency (rpm) | 4200 |

| Exciting Force (KN) | 45 |

| Power (kw) | 11.6 |

| Overall Dimension (mm) | 2150×1660×2550 |

| Pallet Size (mm) | 850×450 |

Notice when using your concrete bricks block plants

Correctly operation is crucial when you use the concrete bricks manufacturing machines. Of course, regular maintenance is also essential. So what should you notice when you use your concrete block machine for sale?

Before starting the concrete block manufacturing equipment, be sure to check the clutch, brake, wire rope, etc. And make sure there is no waste, waste residue and so on in the blender. When the hopper is raised, it must be taken care that no one is allowed to stand under the hopper during this period to avoid accidents. In addition, be sure to cut off the power supply before carrying out inspection or repair of the automatic concrete block machine.

If you want to learn more operation and maintenance methods, welcome to contact us to get more details. Or if you are interested in our concrete block machines for sale, you also can leave your message to us! Our sales manager will reply you as soon as possible!