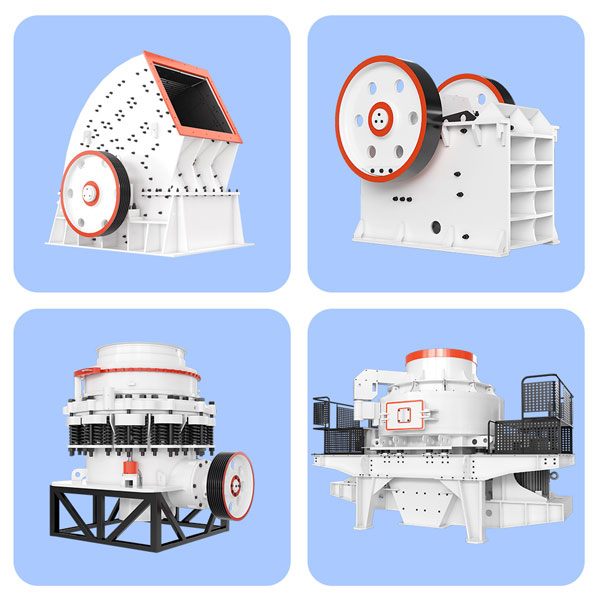

With the gradual depletion of natural sand and gravel resources, and the strong demand for infrastructure construction, there is an increasing demand for artificial sand and gravel aggregates. Therefore, in recent years, the stone crusher machines are highly sought after by customers, and its market prospect is very good. There are many different types of crushers on the market. Today, I will introduce several common stone crusher machines, including:

- Jaw crusher

- Cone crusher

- Vertical shaft impact crusher

- Impact crusher

- Hammer crusher

- Mobile crusher

Jaw Crusher

- Feeding size: 125-1500mm

- Capacity: 1-2200t

Jaw crusher uses the principle of mutual extrusion of jaw plates to process materials for the primary crushing. It can crush ore to medium size, and often forms a complete sand and gravel production line together with cone crusher, impact crusher, sand making machine, etc.

It is commonly used to crush various metal and non-metal ores with compressive strength not higher than 320 MPa, such as river pebbles, granite, limestone, basalt, iron ore, etc.

Features:

- Large crushing ratio and uniform discharge particle size;

- The discharge outlet has a large adjustment range, which is convenient and reliable, and can meet the needs of different customers;

- Simple structure, easy replacement of parts, convenient maintenance, low operating cost;

- Jaw crusher adopts V-shaped deep cavity, crushing without dead Angle, improving feeding capacity and output;

- Low noise and little dust pollution.

Cone crusher

- Feeding size: 65-300mm

- Capacity: 12-1000t

According to different structure, the cone crusher for sale can be divided into spring cone crusher, compound cone crusher, Symons cone crusher, single-cylinder hydraulic crusher and multi-cylinder hydraulic cone crusher.

It is commonly used to crush various ores with medium and above medium hardness (below 350 MPa), such as calcite, granite, river pebbles, etc.

After the material enters the crushing cavity from the feeding port, it is crushed by the mutual impact and extrusion of the eccentric shaft and the rolling mortar wall.

Features:

- Good product granularity. The crushing principle of inter-granular lamination is adopted, so the crushed products are mostly cubic structures, reducing the needle-like materials;

- Simple operation, easy to repair and maintain. Easy to adjust the discharge opening, save time and effort when overhauling, especially the liner plate is easy to replace quickly, reducing downtime;

- Customers can choose standard, medium and short type crushing cavities for coarse, medium and fine crushing operations according to their needs;

- The cone crusher adopts multiple sealing protection devices, which has good sealing performance and is equipped with dust removal and noise reduction devices. These all ensure the cleanliness of the lubricating oil and a good working environment.

Vertical shaft impact crusher

- Feeding size: ≤50mm

- Capacity: 70-640t

Vertical shaft impact crusher is also called sand making machine. With its unique rotor structure design, wear-resistant material process, crushing speed optimization and hydraulic design, it can provide high quality sand and gravel aggregate for highway, high-speed railroad, municipal construction, hydropower dam construction and concrete mixing plant.

It has the characteristics of large processing capacity, stable operation, low consumption of wearing parts, excellent product granularity, thin oil lubrication, automatic maintenance, etc.

Features:

- With a variety of crushing cavity types, it realizes the conversion of stone-on-stone and stone-on-iron, making the finished product excellent in particle shape and reasonable in gradation, suitable for artificial sand making and other fields;

- Reasonable design of the impact angle of the material in the crushing cavity reduces wear and use costs, and increases the output by 30%;

- Automatic detection, safe and reliable. Hydraulic drive cover open, easy for repair and change parts in the crushing cavity, convenient and qucik, save working time.

Impact crusher

- Feeding size: ≤800mm

- Capacity: 30-800t

Impact crusher for sale mainly uses the impact energy to achieve the purpose of material crushing.

The material enters the hammer area from the feeding inlet and is crushed by the impact of the hammer. The material is crushed from large to small into one, two or three impact chambers repeatedly until the material is crushed to a suitable size and discharged by the discharge port.

As a commonly used crusher in secondary crushing, it is suitable for all kinds of medium hardness and softer materials. It adopts a new crushing concept to meet the technological requirements of “more crushing and less grinding”.

Features:

- The gap between the impact plate and the plate hammer is easy to adjust, which can effectively control the size of the discharged material and the finished product has good granularity;

- Use the full hydraulic open device, easy to maintain and change wear-parts;

- New anti-abrasive material makes longer service life of blow bar, impact plate and liner;

- The quality of the hammer directly affects its service life. We have made some improvements to the hammer of the impact crusher, which can extend the service life of the plate hammer very well.

Hammer crusher

Hammer crusher machine includes ordinary hammer crusher and heavy hammer rock crusher machine. It is more suitable for crushing limestone and other medium hardness materials with compressive strength below 200 MPa.

- Ordinary hammer crusher

- Feeding size: ≤350mm

- Capacity: 5-150t

- Heavy hammer crusher

- Feeding size: ≤1000mm

- Capacity: 60-3000t

When working, the motor drives the rotor to rotate at high speed in the crushing cavity, and the material enters the crusher from the inlet. The material is crushed by the impact and grinding effect of the hammer head with high speed movement.

The fine material smaller than the size of the screen hole is discharged through the screen plate, while the coarse material larger than the size of the screen hole is left on the screen plate for further crushing. Users can adjust the gap between the grate bars to change the size of the discharge material.

Features:

- Hammer crusher crushes various stones, one-time molding, no secondary crushing and shaping process, can reduce the cost by about 40%, low energy consumption, low cost;

- The high-quality steel plate welded frame avoids casting defects, more firm and reliable, and ensures the quality of the machine;

- The feed size is large, the discharge size is small, and the finished material can be adjusted to various specifications such as coarse, medium and fine according to demand;

- Advanced structure, reliable performance, large crushing ratio, high productivity, reasonable price and simple operation.

Mobile crusher machine

- Feeding size: Depending on your needs

- Capacity: Custom solution

Mobile crusher machine usually refers to the mobile crushing plant. Mobile crushing plant is mainly used in metallurgy, chemical industry, building materials and other materials that often need to be relocated, and can be divided into tire type and crawler type plant.

According to different crushing process requirements, it can be composed of “crushing first and then screening” or “screening first and then crushing” process, and can also be combined into two screening systems of coarse crushing and fine crushing, or into three screening systems of coarse, medium and fine crushing according to actual needs.

How to choose a suitable stone crusher machine?

After learning the features of different mining rock crushers, you may have such a question, how to choose a right stone crusher machine? There are some factors you should pay attention to:

- Material hardness

- Moisture content of material

- Feeding and discharging size

- Production capacity

Material hardness

Different materials have different hardnesses and structures, which have an important impact on the selection of crushing equipment. The softness and hardness of the material is usually expressed using Mohs hardness, which is divided into ten levels. The higher the level, the harder the material is, the more difficult it is to crush, and the higher the requirements for crushing equipment. For example, the granite has a Mohs hardness of about 6 to 7.

Moisture content of material

The moisture content of the material can also affect the choice of crusher. When the moisture content is too large, the finer material will be agglomerated or directly stick to the coarse material due to the increase of humidity, which increases the viscosity of the material, reduces the discharge speed and makes the productivity decrease. In serious cases, it may even cause blockage of the discharge opening and affect the normal production.

Feeding and discharging size

If the feed size is large and the discharge size is small, secondary crushing or multi-stage crushing is often required. If the size of the material to be crushed is small, multi-stage crushing is generally not needed. Jaw crusher and part of hammer crusher are generally used for primary crushing, while impact crusher, cone crusher, vertical shaft impact crusher, etc. are generally used as secondary crushing or even tertiary crushing.

If the content of coarse material in the raw material is high, then the crushing ratio to be achieved by the stone crusher is larger, so the productivity is lower. If the content of fine material is higher, then the crusher has to achieve a smaller crushing ratio, so the productivity is relatively higher.

Production Capacity

Generally speaking, the higher the output, the larger the size of the crusher required. On the market, the production capacity of rock crushers ranges from a dozen tons to several hundred tons and thousands of tons. Customers can choose the right specification of equipment according to their needs.

Our Contact Details

Daswell Machinery

As a crusher machine supplier with over 30 years experience, our Daswell Machinery can provide you with professional crushing solution. If you have any question, welcome to contact us. We will reply you as soon as possible!

- +86 17752525963

- sales@dwconcretemachine.com