What is construction and demolition waste? The construction and demolition waste can be referred to as C&D waste, which refers to the slag, waste concrete, waste masonry and other wastes generated in the production activities of people engaged in demolition, construction, decoration, repair and other construction industries.

With the development of the economy, people’s living standards have been significantly improved. At the same time, infrastructure construction in various countries is also developing rapidly. The rapid development of infrastructure has resulted in an increasing amount of construction and demolition waste.

The hazards of construction and demolition waste

At present, the main way to deal with C&D waste is landfill and pilling up. Such treatment may cause the following hazards.

Seriously pollute water resources. During the stacking and landfilling of C&D materials, it will cause serious pollution of the surrounding surface water and ground water due to rainwater erosion and surface water or ground water immersion. Once drinking this polluted water, it will cause great harm to the human body.

Affect air quality. In the process of piling construction waste, under the action of temperature and moisture, certain organic substances decompose and produce harmful gases. For example, waste gypsum contains a large amount of sulfate ions, which are converted to hydrogen sulfide under anaerobic conditions, etc.

Damage soil structure and reduce soil quality. After long-term exposure to the sun and rain, the harmful substances in the C&D waste piled up in the open air will penetrate into the soil, thus triggering a series of physical, chemical and biological reactions, thus reducing the quality of the soil. In addition, small stones in the construction waste will also enter the soil, change the material composition of the soil, damage the structure of the soil.

Prospects for construction and demolition waste recycling

For these construction wastes, there is another way to recycle them. The treated construction waste can be used as concrete aggregate for road and other infrastructure construction. Discarded pavement asphalt can also be used to regenerate asphalt concrete after treatment. Scrap metal can be reused directly or after secondary processing. It can be seen that construction waste is not real waste, but a resource waiting to be discovered and used.

In recent years, governments around the world have begun to issue environmental regulations to encourage people to convert construction waste into new types of aggregates through equipment such as mobile or portable rock crushers. This also shows that the future market for construction waste recycling is huge.

How to recycle the C&D waste?

The process of recycling C&D waste mainly includes the following aspects.

Pro-processing. According to the different components, C&D waste can be divided into muck, concrete blocks, brick and tile fragments, waste mortar, mud, asphalt blocks, scrap metal, etc. Therefore, it is necessary to sort the waste first and remove large impurities and so on.

Crushing. Crush large pieces of construction waste into smaller pieces.

Screening. Screen the crushed material. The materials that meet the specifications will become finished products, and those that do not meet the specifications will be returned to the crusher for secondary processing.

Grinding. If you want to get a finer material, you need to choose a different mill to grind the crushed product.

Although construction and demolition waste is increasing in a large amount, as long as it is properly handled, it can become a useful material.

Choose the right equipment for processing C&D waste

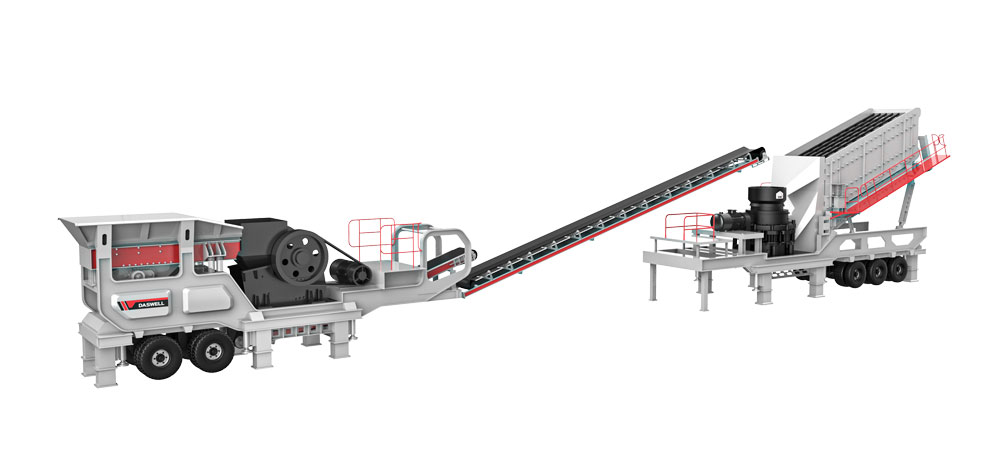

At present, there are many equipments on the market for processing construction waste, such as cone crushers, sand making machines, etc. But if you want to choose the most suitable equipment, then I strongly recommend everyone to choose the mobile crushing plant.

There are two main reasons for choosing the mobile crushing plant to deal with the C&D waste.

Construction waste is mostly piled up in urban areas or densely populated places. This kind of place has a relatively small space and has certain limitations. The mobile crushing plant occupies a small area, and is more convenient to install, disassemble and move.

In addition, the mobile crushing station adopts the integrated unit model, which reduces the complex infrastructure installation and other work of the split unit, and reduces the consumption of materials and time.

Advantages of mobile crushing plant

The mobile crushing plant includes two different types, one is tire type mobile plant and the other is crawler type plant. The transition of the tire crushing plant mainly relies on the traction of the semi-trailer, while the crawler type adopts the way of self-hydraulic drive.

Flexible mobility. The mobile crushing plant has a high vehicle chassis and a small turning radius, which is convenient for driving on ordinary roads and even rough roads. Save time for quick entry into the site. At the same time, it also provides more flexible space for the overall layout of the crushing production line.

Reduce the transportation cost of materials. The mobile crushing line can crush materials on-site, eliminating the intermediate link of transporting materials away from the site and then crushing them, which greatly reduces the transportation cost of materials.

A variety of configuration options, strong adaptability. According to the requirements of different customers for coarse crushing, fine crushing or screening, the mobile crushing station can not only work alone, but also flexibly form different production lines to work together.

If you want to learn more information about how to choose a suitable crusher equipment or how to deal with the construction and demolition waste, welcome to contact us without hesitate. Our professional team will provide you with services.