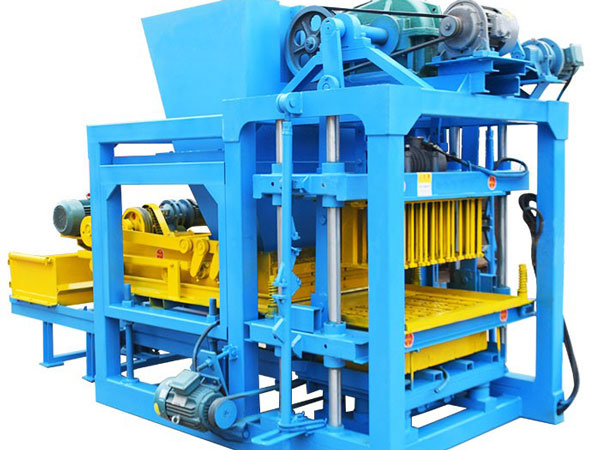

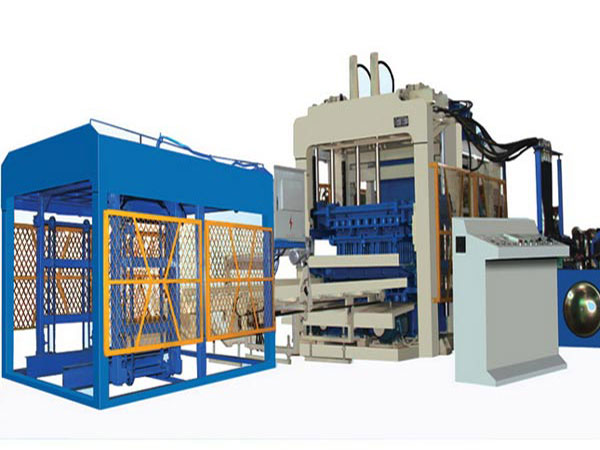

Brick making machine for sale is a machine used to produce various of block bricks. This brick maker machine for sale is a new modern machine. Compared with traditional method for producing bricks, our machine has made innovations and improvements. Our brick making plant for sale produces the bricks without burning, not only greatly improving the production efficiency, but also reducing the environmental pollution. As our customers’ requirements for finished bricks increase, our machines are constantly changing to meet their needs. Our Daswell brick machine maker is popular. Up to now, we have exported our products to over 60 countries, including Philippines, Indonesia, Mexico, Thailand, Malaysia, etc. If you have any need, welcome to contact us now!

| Model | BMM12-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1728-2160 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 12700-14400 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1300×900 |

| Exciting Force(KN) | 110 |

| Overall Power(KW) | 67 |

Types of brick making machines

The brick manufacturing machine includes a variety of types. So no matter what kind of bricks manufacturing plant you want to purchase, you can pick out a satisfied product from our company. Now let me briefly introduce to you the classification of our brick factory machine.

According to the mobility, it can includes stationary type and mobile type. The difference between these two machines is whether they have wheels. Those customers who need to move the machine frequently are more willing to buy the mobile type.

According to its control system, the brick making business for sale can be divided into fully automatic type, semi automatic type and manual type. Their differences are the advanced level of control system.

In addition, according to their production capacity, the brick plant for sale includes large size, medium size and small size. You should consider the scale of your projects when thinking about what size of equipment you should buy.

If you have any question about choosing a suitable machine to manufacturer bricks, welcome to consult us at any time.

| Model | BMM4-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 720-960 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 5930-6720 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4600 |

| Pallet Size(mm) | 1020×570 |

| Exciting Force(KN) | 55 |

| Overall Power(KW) | 27.5 |

| Model | BMM5-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 900-1200 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 7680-8800 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1100×570 |

| Exciting Force(KN) | 60 |

| Overall Power(KW) | 32 |

Features and specifications of brick making machine for sale

- Our BMM series brick manufacturing machine for saleis the hot sale product. Its specifications include BMM4-15, BMM5-15, BMM6-15, BMM8-15, BMM10-15, BMM12-15, etc. Of course, we also have other models of machines.

- The production capacity of our brick making machine for salecan meet the demands of different size projects whether it is small or large.

- High-quality product and low failure rate. The main parts and components of the equipment adopt international brands, such as Schneider, Siemens, etc., with reasonable design structure and advanced technology.

- Highqualified rate of finished brick. Our brick making plant has strong excitation force, so the products are of high strength.

- High automatic degree and save labor cost. This brick maker machineis highly automated and can save labor cost. The whole equipment can be operated by only 4 to 6 workers.

- Easy operation and maintenance. Modular design makes the operation and maintenance easier.

| Model | BMM6-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1080-1440 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 7680-8861 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4500-5100 |

| Pallet Size(mm) | 900×700 |

| Exciting Force(KN) | 65 |

| Overall Power(KW) | 28 |

| Model | BMM8-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1200-1600 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 9000-10000 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 950×900 |

| Exciting Force(KN) | 85 |

| Overall Power(KW) | 51 |

Its raw materials and finished bricks

One of the advantages of our brick manufacturing equipment is its low raw material cost. Why? It can takes various of materials as its raw materials, such as, fly ash, sand, little stone, cement, construction waste, slag, steel slag, coal gangue, cinder, etc. These raw materials are not only cheap, but also relatively easy to get. You only need two or three of the above ingredients to make bricks.

As for its finished bricks, our brick forming machine can produce different shape and size of bricks as long as you change its molds. It can produce hollow bricks, interlocking bricks, solid bricks, colored bricks, grass plating blocks, etc. The same of brick making machines for sale has different capacity for making different types of bricks. For example, the BMM4-15 brick making equipment can produce 720 – 960 hollow bricks per hour, while produce 5930 – 6720 solid bricks per hour.

Our brick manufacturing plant has wide application on the wall decoration, water conservancy slope protection project, road construction, municipal landscape engineering, etc.

| Model | BMM10-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1440-1800 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 11011-12480 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1100×900 |

| Exciting Force(KN) | 110 |

| Overall Power(KW) | 67 |

| Model | BMM12-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1728-2160 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 12700-14400 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1300×900 |

| Exciting Force(KN) | 110 |

| Overall Power(KW) | 67 |

How to make bricks

Because of its high automatic degree, the BMM series of brick making process is simple. Knowing its working process can help you operate this machine better. The brick manufacturing process mainly includes five steps: set the ratio of raw materials, add the water and stir all materials, high pressure vibration forming, let dry for a short time, deliver the finished bricks.

At the beginning of making your bricks, you need to ensure what types of finished bricks you need and kind of raw materials you are easy to get. If you have any requirement for the hardness and size of finished bricks, you can tell our engineers in advance. They can help you select a suitable mold and brick wall making machine.

Build your own brick making machine

With the booming development of the construction industry, more and more customers are willing to invest in a brick plant machinery. If you want to build your own brick making machine, you should pay more attention to many aspects.

First of all, you should look for a reliable and reputable manufacturer. Maybe there are a lot of brick machine manufacturers on the market. But you should judge which manufacturer is worthy of your trust. Finding a credible manufacturer can help you get a good bricks plant at the most favorable price.

Then you need to pick out a right type and model of machine. Right bricket machines can not only guarantee the working efficiency, but also save your initial purchase cost. Finally, learn the after-sale service of your manufacturer in detail. That is because the level of after-sales service will affect the speed of troubleshooting and your maintenance cost.

As a brick machine manufacturer in China, our Daswll Machinery has accumulated rich experience. If you want to find a trustworthy supplier, please don’t hesitate to choose our company!

| Model | DMBE-12A |

| Molding Quantity | 12pcs/mould(400*200*200mm) |

| Cycle Time | 25s |

| Production Capacity | 1700pcs/hour |

| Operation Pressure | 16-20Mpa |

| Vibration Mode | Excitation |

| Demolding mode | Hydraulic |

| Total Power | 17.5Kw |

| Total Weight | 5100KGS |

Request a quote

After learning this article, if you are interested in our brick making machine for sale, welcome to contact us and request a quote! You can send the email to us. Of course, you also can click the button “Request A Quote” and fill out the form and tell us what you want to know. After receiving your message, our salesman will reply you as soon as possible because we will provide you with 7*24 hours service! Looking forward to your message!