Hollow block making machines are mainly used to produce the high-quality hollow bricks. Of course, it also can produce other kinds of bricks as long as you change its molds. Our BMM series hollow block machine for sale is popular among the customers due to its high production quality, high production capacity, strong adaptability, reliable performance, long service life and so on. As a well-known hollow block machine manufacturer, our Daswell Machinery has exported many sets of this machine to abroad, such as, Philippines, Mexico, Pakistan, Moldova, Kazakhstan, Indonesia, South Africa, USA, Zambia, etc. Rich exportation experience makes us provide you with better service. Therefore, if you plan to buy a brick machine, contact us now!

| Model | BMM4-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 720-960 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 5930-6720 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4600 |

| Pallet Size(mm) | 1020×570 |

| Exciting Force(KN) | 55 |

| Overall Power(KW) | 27.5 |

| Model | BMM5-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 900-1200 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 7680-8800 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1100×570 |

| Exciting Force(KN) | 60 |

| Overall Power(KW) | 32 |

Wide applications

As you know, our hollow block make for sale can produce all kinds of bricks. Our hollow block maker machine can set the molding parameters according to the requirements of different types of brick. And its molding speed is fast, greatly meet the needs of customers to produce all kinds of brick. Moreover, these finished bricks can be applied in the different fields. Here is a brief introduction.

According to the shape of the bricks, the hollow brick making machines can produce the hollow bricks, solid bricks, interlocking bricks, etc.

According to the usage of the bricks, it can make the following bricks: the wall bricks, flower bed bricks, permeable bricks, archaize brick, road brick, grass plating brick, kerb brick, slope protection brick, etc.

Different types of bricks need different kinds of raw materials and ratio. If you have no idea, you can send email to us and ask our salesman. You can use these finished bricks on the road construction, wall decoration, garden construction and so on.

| Model | BMM6-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1080-1440 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 7680-8861 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4500-5100 |

| Pallet Size(mm) | 900×700 |

| Exciting Force(KN) | 65 |

| Overall Power(KW) | 28 |

| Model | BMM8-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1200-1600 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 9000-10000 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 950×900 |

| Exciting Force(KN) | 85 |

| Overall Power(KW) | 51 |

Automatic hollow block making machine

The hollow brick manufacturing machine has different configurations to meet the need of different customers. So depending on its advanced degree of the control system, the hollow block brick making machine includes fully automatic type, semi automatic type and manual type.

In recent years, the fully automatic hollow block machine becomes more and more popular. It can not only greatly improve the production efficiency, but also reduce the labor intensity and save the labor cost. So more and more customers want to invest in a fully automatic hollow block making machines.

The fully automatic concrete hollow block machine for sale are controlled by the PLC control system. It can automatically weigh the raw materials, place the plates and so on. It just takes several workers to operate the whole producing process. Our BMM series hollow block machine maker has their standard configuration. But we also can customize for you according to your actual needs and the purchase budget.

| Model | BMM10-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1440-1800 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 11011-12480 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1100×900 |

| Exciting Force(KN) | 110 |

| Overall Power(KW) | 67 |

| Model | BMM12-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1728-2160 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 12700-14400 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1300×900 |

| Exciting Force(KN) | 110 |

| Overall Power(KW) | 67 |

Complete hollow block production line

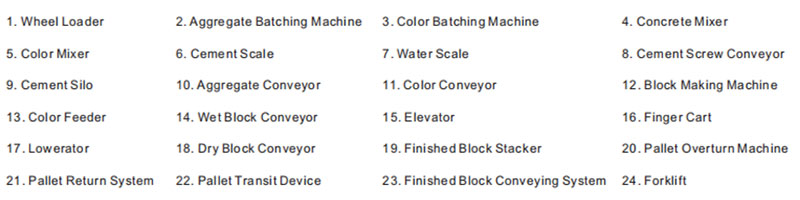

Some of our customers just need to purchase the hollow block making machine for sale. But others need us to help them configure a complete hollow block production line. A complete block production line includes the following components: wheel loader, aggregate batching machine, color batching machine, concrete mixer, cement screw conveyor, hollow block machine, finger cart, finished block stacker, etc.

From loading the raw materials to molding and transportation, the complete production line can make your operation become easier. If you have a big project, a complete block production line is an ideal choice for you. Higher levels of mechanization mean higher productivity of your hollow bricks machine and lower labor costs. This can reduce the cost of finished bricks and the sales price, and also improve sales volume and increase profits.

If you want to learn more detailed information about the brick production line, welcome to contact us and learn more details.

Select the suitable hollow block maker

Selecting a suitable holo bricks plant needs to consider many aspects. Of course, if you can find a reliable manufacturer, they will give you some professional advice. As a reputable manufacturer, our Daswell Machinery Co., Ltd has received high praise from our customers. You can consult us if you trust our company.

First of all, you should think about the type of the hydraulic hollow block making machines, mobile type and stationary type. This will depends on whether you need to move your machine frequently. Then, you should consider its specifications. The models of our BMM series machine include BMM4-15, BMM5-15, BMM6-15, BMM8-15, BMM10-15 and BMM12-15. This depends on the bricks demand of your projects. At last, the configurations and parameters are also important. In addition, you also pay more attention to the types of the control system.

If you are interested in our Daswell concrete hollow block making machines, you can send email to us and tell us your requirements. Then our salesman will reply you quickly and give you more professional advice.

| Model | BMM4-26 |

| Capacity

(for 390×190×190mm hollow brick) (pcs/h) |

375-500 |

| Molding Cycle (s) | 26 |

| Vibration Frequency (rpm) | 4200 |

| Exciting Force (KN) | 45 |

| Power (kw) | 11.6 |

| Overall Dimension (mm) | 2150×1660×2550 |

| Pallet Size (mm) | 850×450 |

| Model | BMM4-40B |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 250-312 |

| Molding Cycle(s) | 240 |

| Vibration Frequency(rpm) | 2800 |

| Pallet Size(mm) | 850×450 |

| Exciting Force(KN) | 40 |

| Overall Power(KW) | 9.3 |

How much is a hollow block machine?

The hollow block making machine price is the key factor that many customers are concerned about. There are many factors affecting the hollow block machine price, such as, types and models, the quality of components, etc. Moreover, the different manufacturers will provide you with different quotes. In order to buy the machine at the most competitive price, you can compare different quotes from different hollow block machine manufacturers.

Here are some useful tips for minimizing your hollow bricks machine price. Look for a credible manufacturer whether online or offline; Choose a suitable model of hollow blocks maker for sale; High-quality product can your maintenance cost; Choose suitable raw materials and transportation method, etc.

Choose our company, we must spare no effort to help you pick out the suitable hollow bricks machine, transportation method and so on.

Correctly operation is important

Correctly operating the hollow block maker manual can not only improve its working efficiency, but also reduce the failure rate and prolong its service life. So before using your machine, your operators need to be trained. Choose our company and our engineers will provide you with the training service.

Operators must understand the instructions, familiar with the working principles and procedures, in accordance with the requirements of the operation of equipment. The power must be cut off when the hollow block maker machine for sale stops working or when repairing. Clean and inspect your hollow block making plant regularly to keep it clean. If something goes wrong with the hollow block manufacturing machines, the operator needs to stop the machine immediately for inspection.Wait for the failure to discharge before continuing to operate the machine.

All in all, we are glad to receive your message for inquiring the price of our hollow block making machines. You also can click here to learn more information. We will reply you in 24 hours!