Crushing plant for sale consists of a series of machines designed for rock crushing, construction waste crushing, garbage crushing, or other types of crushing operations. The crushing screening plant can crush various of materials, such as, river pebbles, granite, basalt, limestone, iron ore, quartz, copper ore, etc. The quality of sand and gravel aggregate produced by our plant is high. Generally, a complete crushing production line needs to be customized according to the size of shape of your raw materials, the desired particle size of the end products and so on. So you need to look for a trustworthy supplier to design it for you. Our Daswell Machinery is a good choice for you!

Type of crusher plant

The type of crusher plant is different due to different classification standard. In order to meet the demands of different clients, we produce various kinds of crushing and screening plant for them.

According to its mobility, the crushing and mining equipment includes stationary type and mobile type. Mobile type plant is a new modern type, which is more suitable for those small or medium size of projects. It can move quickly from one site to another. The stationary type plant is more suitable those projects that have long production period and don’t need to move it frequently. Stationary type crushing equipment for sale is with the characteristics of high production capacity, stable performance, strong adaptability and so on.

According to the difference of their main crusher machine, the crushing machine is also called jaw crushing plant, cone crushing production line, etc. As one of the most important parts for a crushing plant, the selection of the crusher machine depends on the size and hardness of your raw materials and the size of the finished products you desires.

| Max. Feeding Size(mm) | Capacity(t/h) | Primary Crusher | Secondary Crusher | Aggregate/Sand Size(mm) |

| 340 | 30-50 | PE400×600 jaw crusher | PF1008 impact crusher | 0-5, 5-10, 10-20, 20-50 or other different sizes as demand |

| 420 | 50-80 | PE500×700 jaw crusher | PF1010 impact crusher/

CS75 cone crusher |

|

| 480 | 70-100 | PE600×900 jaw crusher | PF1210 impact crusher/

CS90 cone crusher |

|

| 560 | 90-150 | PE750×1060 jaw crusher | PF1214 impact crusher/

cone crusher |

|

| 630 | 140-350 | PE900×1200 jaw crusher | PF1315 impact crusher/

CS75 cone crusher |

|

| 700 | 350-500 | PE1000×1200 jaw crusher | PF1315/2 impact crusher/

CS75 cone crusher |

Crushing plant layout

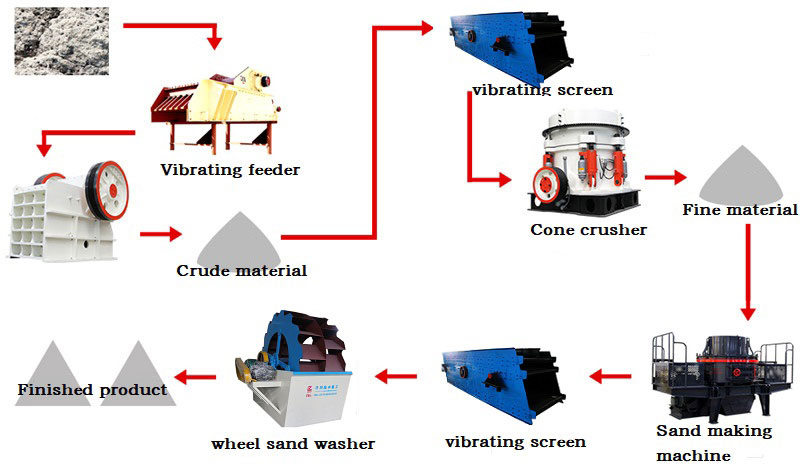

Different crushing stone plant has different configurations. Of course, different purposes also lead to different configurations of the crushing plant for sale. In usually, a crushing production line includes feeders, crusher machine, vibrating screen, belt conveyor, control system and so on. In addition, if you need, we also can equip with related sand making machine and sand washing machine for your crushing plants for sale. Now, I will introduce the main components of the crushing and screening equipment for you.

Vibration feeders are machines that feed impact and jaw crushers with stones and rocks requiring crushing.

Crusher units are machines that crush raw materials using a range of different techniques. Examples of crusher units include jaw crusher, cone crusher, hammer crusher, impact crusher, etc.

Vibrating screen. A vibrating screen is used to separate materials into different sizes. Particles that are still big when they come out of a crusher can then be sent back through.

Control system. Modern plants have central electric PLC control systems that are used to monitor and control all operations.

Working process of crushing plant for sale

The working process in a crushing mining equipment can include four stages.

First, the raw materials are fed into a jaw crusher via a belt conveyor system. The jaw crushing equipment is used for primary crushing and can break up large stones ready for secondary and tertiary crushing machines.

Then, the crushed materials are transported to a secondary crushing machine, again via a conveyor belt system, before being transported to the vibrating screen for separation.

Next, the vibrating screen separates qualified materials from those that require re-crushing. The vibrating screen settings used will depend on the specifications of the requested final product.

Finally, stone materials that requires re-crushing is sent back through all the crusher units in the crushing device. A dust control unit is needed in many plants to remove the dust pollution.

The working process of crushing screening plant equipment is simple, which makes its operation become easy.

| Max. Feeding Size(mm) | Capacity(t/h) | Primary Crusher | Secondary Crusher | Aggregate/Sand Size(mm) |

| 340 | 30-50 | PE400×600 jaw crusher | PF1008 impact crusher | 0-5, 5-10, 10-20, 20-50 or other different sizes as demand |

| 420 | 50-80 | PE500×700 jaw crusher | PF1010 impact crusher/

CS75 cone crusher |

|

| 480 | 70-100 | PE600×900 jaw crusher | PF1210 impact crusher/

CS90 cone crusher |

|

| 560 | 90-150 | PE750×1060 jaw crusher | PF1214 impact crusher/

cone crusher |

|

| 630 | 140-350 | PE900×1200 jaw crusher | PF1315 impact crusher/

CS75 cone crusher |

|

| 700 | 350-500 | PE1000×1200 jaw crusher | PF1315/2 impact crusher/

CS75 cone crusher |

Crushing machine suppliers

In recent years, the crushing plant for sale becomes more and more popular. You can find many suppliers on the market. The selection of the crushing machine suppliers is very crucial. They will determine whether or not you can buy a good crushing equipment, whether or not you buy your machine at the most competitive crushing plant price and whether or not you can enjoy the considerate service. Therefore, before you choose your supplier, you need to know as much as you can about it.

You can get an idea of their production strengths by visiting their factories. Maybe you can find more information online about these suppliers, but visiting their factories is the most direct methods for you. Moreover, you should compare different quotations offered by different crushing equipment manufacturers. In the case of the same quality, you should choose a more advantageous manufacturer in price.

In addition, when comparing different crushers, it’s important for buyers to look at technical specifications carefully. The moisture content, hardness, and reduction ratio of the raw materials, a customer wants to process are key factors that determine the most suitable crushing and screening plants to buy.

Crushing plants in working site

As we all know, the crushing mining equipment has wide usage on the different fields, such as expressway construction, high speed railway construction, water conservancy project, port and dock construction and so on. The high-quality sand and gravel aggregate produced by good crushing machine will guarantee the quality of the whole project.

As a experienced crushing plant manufacturer, our Daswell Machinery is credible for you. Whether you want to buy a single crusher machine or a complete crushing production line, we can provide you with a perfect solution. Up to now, we have exported many sets of crushing and screening plant to abroad, including Egypt, Czech Republic, Kenya, South Africa, Vietnam, Malaysia, Iran, etc. Meanwhile, our machines have won good reputation from our customers.

In summary, choose our Daswell Machinery if you want to get a good crushing plant for sale at the favorable price.