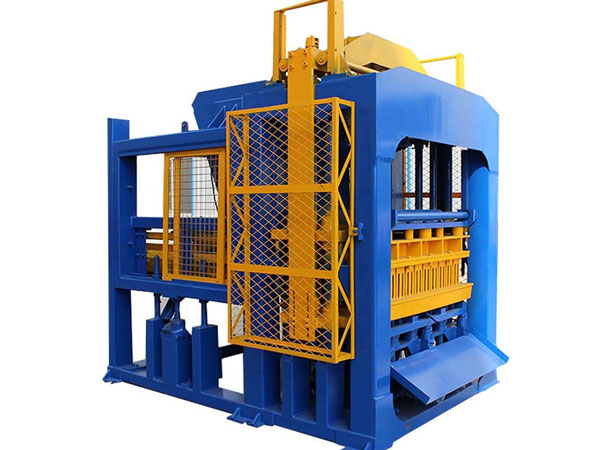

As its name suggests, the fly ash brick making machine mainly takes the fly ash as its main raw materials. This type of raw materials is not only easy to get, but also can save your material costs. The BMM series fly ash bricks machine is popular in recent years. That is not only because it can produce high-quality fly ash bricks, but also because it also can produce other types of bricks, such as, standard bricks, solid bricks, as long as you change the molds. Choose the different molds, you can get the different shape and sizes of finished bricks. The fly ash brick manufacturing plant with better quality and reliable performance is produced by our Daswell Machinery.

| Model | BMM6-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1080-1440 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 7680-8861 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4500-5100 |

| Pallet Size(mm) | 900×700 |

| Exciting Force(KN) | 65 |

| Overall Power(KW) | 28 |

Benefits of fly ash brick machine

- Wide range of raw materials, low operating costs. Besides the fly ash, you also can use the cement, construction waste, cinder, etc as its raw materials. These materials are very cheap, which can greatly reduce your operating costs.

- High automated degree and easy operation. Our fly ash bricks manufacturing process adopts the PLC plus computer control system, making the operation simpler and easier.

- High productivity. High automatic degree improves the production capacity of the fly ash block making machine. Moreover, this machine has shorter molding cycle, which can help you get more bricks in the short time.

- Low labor costs. Because of its high automatic degree, you just need several workers to operate the whole working process. Hiring fewer workers is a great way to lower your labor costs.

- Use the international famous brand parts. Equipped with high-quality and credible parts, this will guarantee the quality of our fly ash brick making machine for sale. Meanwhile, this can reduce its failure rate and increase its service life.

| Model | BMM4-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 720-960 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 5930-6720 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4600 |

| Pallet Size(mm) | 1020×570 |

| Exciting Force(KN) | 55 |

| Overall Power(KW) | 27.5 |

| Model | BMM5-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 900-1200 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 7680-8800 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1100×570 |

| Exciting Force(KN) | 60 |

| Overall Power(KW) | 32 |

What should you notice when you buy the fly ash machine?

If you want to purchase a suitable and cost-efficient ash brick machine, here are some aspects you need to consider.

First of all, you need to consider the total production capacity of the machine before buying one. For instance, if you are looking for an automatic fly ash brick plant for building your home, you can choose a small scale option. If you are planning to produce bricks in large scale, you should choose a large scale fly ash manufacturing machine.

Then, its control system is also important. There are fully automatic fly ash brick making machine, semi automatic fly ash bricks machines and manual type for your selection. The choice of control system depends on whether you need to produce a large number of bricks in a short time.

Finally, pay more attention to its quality. The overall quality of the bricks produced depends on the quality of the fly ash brick making plant. Choose the best machine made from high quality materials to ensure durability and reliable production of bricks for various uses.

| Model | BMM6-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1080-1440 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 7680-8861 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4500-5100 |

| Pallet Size(mm) | 900×700 |

| Exciting Force(KN) | 65 |

| Overall Power(KW) | 28 |

| Model | BMM8-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1200-1600 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 9000-10000 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 950×900 |

| Exciting Force(KN) | 85 |

| Overall Power(KW) | 51 |

How to start a fly ash brick business?

Are you building a home? Are you starting a business of selling building blocks? Well, you don’t need to make bricks by hand for any of these reasons. Rather, you can invest in a good fly ash bricks manufacturing unit for the best results. When you want to start a fly ash brick business, you don’t need a lot of investment cost.

You can invest in a single ash brick plant. Besides that you also can invest in a complete fly ash brick production line. Before you start your business, you need to plan your site and choose the suitable raw materials. Then choose the satisfied automatic fly ash brick making machine and manufacturer. At last, after installing and debugging your fly ash block machine, you can start it immediately.

Of course, when you meet some problems during using the fly ash brick machine for sale, you can ask your manufacturer for the help. They can help you solve your problems quickly.

| Model | BMM10-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1440-1800 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 11011-12480 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1100×900 |

| Exciting Force(KN) | 110 |

| Overall Power(KW) | 67 |

| Model | BMM12-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1728-2160 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 12700-14400 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1300×900 |

| Exciting Force(KN) | 110 |

| Overall Power(KW) | 67 |

Easy And convenient to maintain this machine

Of course, when you are looking for a good automatic hydraulic fly ash brick making machine, you might look at the features, workmanship and the ease of use. However, most people forget to consider serviceability of the machine.

Just like any other machine, you need to prepare for routine maintenance for your fly ash bricks plant. With proper maintenance, the machine can operate efficiently and maintain durability. Therefore, you can count on long-term operation without any breakdowns or repairs.

A fully automatic fly ash brick plant that is easy to maintain is the best choice for your needs. Also, you should consider the availability of spare parts in the event that the machine breaks down during operation. When you buy the ash brick manufacturing plant, you also can store some quick-wear parts. Quickly changing the wearing parts can reduce your downtime.

| Model | DMBE-12A |

| Molding Quantity | 12pcs/mould(400*200*200mm) |

| Cycle Time | 25s |

| Production Capacity | 1700pcs/hour |

| Operation Pressure | 16-20Mpa |

| Vibration Mode | Excitation |

| Demolding mode | Hydraulic |

| Total Power | 17.5Kw |

| Total Weight | 5100KGS |

| Model | BMM4-40B |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 250-312 |

| Molding Cycle(s) | 240 |

| Vibration Frequency(rpm) | 2800 |

| Pallet Size(mm) | 850×450 |

| Exciting Force(KN) | 40 |

| Overall Power(KW) | 9.3 |

Choose our Daswell Machinery

Although you can find lots of manufacturers on the market, choosing a credible manufacturer is necessary. Our Daswell Machinery is a experienced brick block making machine supplier. Since our company was founded, we have accumulated over 30 years production experience. As an exporting company, we also help many customers purchase a suitable and good-quality automatic fly ash brick machine.

Besides providing you with good automatic fly ash bricks plant, our professional team also can offer you considerate service, such as, answer your questions, help you choose the right models, plan your site, etc. In addition, we also set up several branch offices and warehouses to serve our customers better, such as in Philippines, in Egypt, etc. You can enjoy the most thoughtful service from us.

Good reputation from our customers

Besides rich production experience, we also have about ten years exportation experience. Up to now, we have exported our automatic plant for fly ash brick manufacturing to many countries, including Philippines, Mexico, India, Thailand, Indonesia, Fiji, Pakistan, South Africa, etc. After using our fly ash bricks plant for a while, some of our customers send us some pictures or video of the machine at work. They give high praise to the quality of our fly ash brick maker for sale and our sincere service.

If you also need a machine like our fly ash brick making machine, please don’t hesitate to contact us. And you can get a reply as soon as possible!