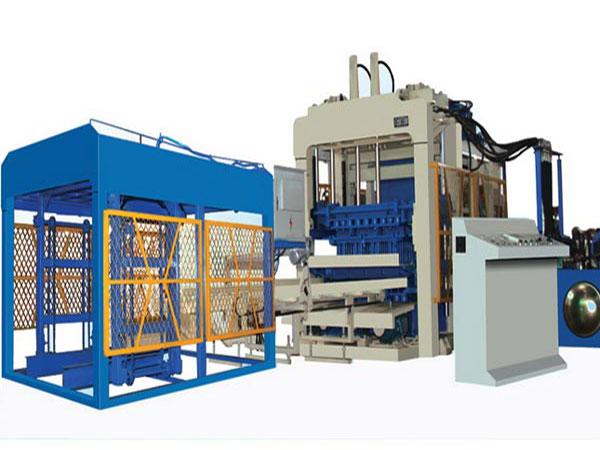

The fully automatic brick making machine is a popular machine in recent years due to its high automation degree. With the development of environmental protection building materials on the market, ordinary clay bricks have been replaced by baking-free bricks. The customers have higher requirements on the brick block machine. So the fully automatic block making machine that can meet the customer’s high and more diverse needs appears on the market. Its raw materials are rich in variety and wide sources. It doesn’t matter if you use cinders or river sand as the raw materials for your equipment. Our Daswell Machinery is a well-known brick machine supplier. If you have any need, welcome to contact us now!

| Model | BMM4-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 720-960 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 5930-6720 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4600 |

| Pallet Size(mm) | 1020×570 |

| Exciting Force(KN) | 55 |

| Overall Power(KW) | 27.5 |

Types of fully automatic brick machine

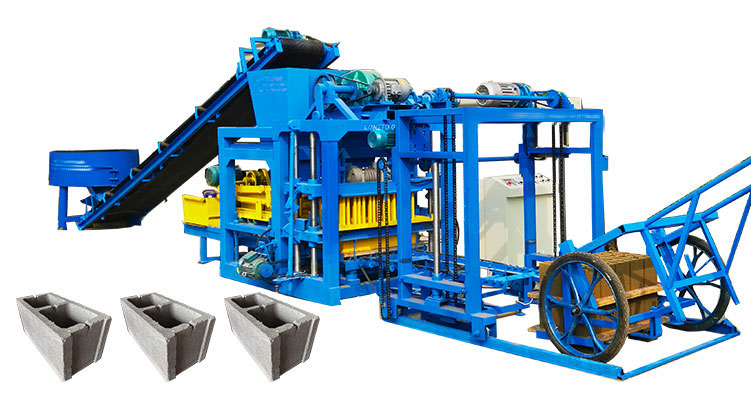

Fully automatic hollow block machine

This type of machine can produce hollow bricks with high production capacity. You can get different pieces of hollow bricks depending on the model of fully automatic hollow block machine you choose. Of course, according to the difference of finished bricks, we also have fully automatic solid brick equipment, fully automatic interlocking brick plant, etc.

Fully automatic fly ash brick maker

This type of block machine mainly takes the fly ash as its raw material, which can greatly reduce your raw material costs. Moreover, this type of raw material is easy to get, so this can reduce the transportation time of the raw materials. Besides the fly ash brick machine, we also can provide you with fully automatic concrete brick plant fully automatic cement brick maker, etc.

In addition, besides these machines, the automatic brick making machine also includes fully automatic type, semi automatic type and manual type according to their automation degree. You can purchase a right fully automatic brick making plant no matter what requirements you have for this machine.

| Model | BMM4-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 720-960 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 5930-6720 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4600 |

| Pallet Size(mm) | 1020×570 |

| Exciting Force(KN) | 55 |

| Overall Power(KW) | 27.5 |

| Model | BMM5-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 900-1200 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 7680-8800 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1100×570 |

| Exciting Force(KN) | 60 |

| Overall Power(KW) | 32 |

Check out its parameters

When you select the specification of your automatic brick making machine for sale, you should pay attention to its parameters.

On the one hand, you need to be concerned with its production capacity. For example, the BMM4-15 automatic brick making plant produces the hollow blocks 4pcs/mould while the BMM8-15 produces hollow bricks 8pcs/mould. Moreover, the BMM4-15 automatic brick manufacturing machine can manufacture the hollow blocks 720-960pcs/h. By contrast, the BMM8-15 can produce the hollow bricks 1200-1600pcs/h.

On the other hand, there are other parameters you also need to notice. The forming time of automatic brick manufacturing plant needs about 10-15s. And they all are controlled by the PLC system. Meanwhile, the power is also important. Let’s take the BMM6-15 fully automatic brick making machine as the example. Its overall power can reach 28kw. Meanwhile, its main vibration form is platform vibration.

| Model | BMM6-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1080-1440 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 7680-8861 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4500-5100 |

| Pallet Size(mm) | 900×700 |

| Exciting Force(KN) | 65 |

| Overall Power(KW) | 28 |

| Model | BMM8-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1200-1600 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 9000-10000 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 950×900 |

| Exciting Force(KN) | 85 |

| Overall Power(KW) | 51 |

Characteristics of automatic brick machine

- High levels of automation. The best automatic block making machines are fitted with advanced electronic PLC systems that control all stages of production. Furthermore, sophisticated fault diagnosis systems ensure that malfunctions or errors are quickly detected and automatically rectified. The automatic control system can be also manually overridden, allowing businesses to operate the machines in manual mode if necessary.

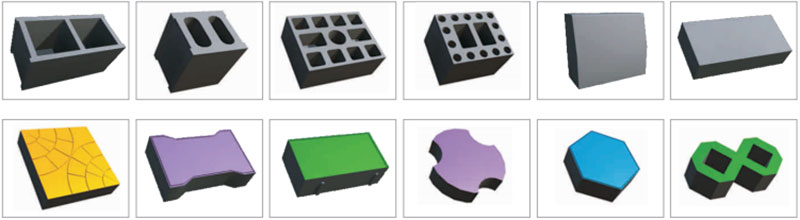

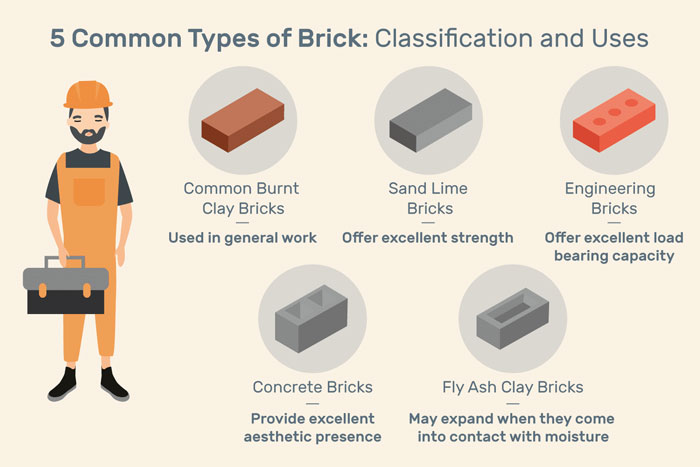

- Produce all kinds of bricks. With an automatic brick plant, you can manufacture a wide range of different brick types. This doesn’t just mean changing the raw material, you can also change the shape, size, and style of block switching the machine’s molds. Some of the types of bricks can manufacture include concrete hollow blocks, solid brick, interlocking bricks, H-paver, curbstone bricks, etc.

- Low labor costs. One of the biggest costs traditionally associated with brick manufacturing is manual labor. Meanwhile, an auto brick making machinecan be operated with a very scaled back manual workforce, reducing labor costs considerably.

| Model | BMM10-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1440-1800 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 11011-12480 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1100×900 |

| Exciting Force(KN) | 110 |

| Overall Power(KW) | 67 |

| Model | BMM12-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1728-2160 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 12700-14400 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1300×900 |

| Exciting Force(KN) | 110 |

| Overall Power(KW) | 67 |

Fully automatic type VS Semi automatic type

Maybe many customers want to know the difference between fully automatic brick making plant and semi automatic brick machine in order to choose a better one. They have their different advantages.

For the automatic block machine, it has advanced control system, PLC control system, which makes it have higher production output. If you need lots of bricks in a short time, the automatic brick block making machine is fit for you. What’s more, high automatic degree can reduce the labor intensity and save your labor costs.

For the semi automatic brick making plant, it is smaller in size and lighter in weight. You don’t need much space to put the semi automatic block making machine, which reduces the floor space of your machine. Meanwhile, the semi automatic brick making machine price is low, so you don’t worry about your original investment cost.

Choose more suitable one according to your real needs.

| Model | BMM8-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1200-1600 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 9000-10000 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 950×900 |

| Exciting Force(KN) | 85 |

| Overall Power(KW) | 51 |

The reasons that this machine can help you obtain great benefits

Why would investing in an automatic brick machine for sale give you a great benefits? There are some reasons.

Firstly, the raw materials of the fully automatic brick making machine plant is very low. Bricks can be manufactured from fly ash, sand, slag, river stone, and construction waste using an automatic block maker. So this can reduce your original cost. Then the fully automatic brick plant has high production capacity. Fully automatic control system can ensure it can run continuously. You can get lots of high-quality bricks.

If you use these bricks by your own, they will guarantee the quality of your projects But if you use them for selling, they will win good reputation and great profits from your customers. Finally, its quick return can help you earn more money. Whether you want to invest in a complete brick production line or a single brick machine, you can get a satisfied machine from our company.

Welcome to visit our production factory

If you want to know more about the automatic brick machine manufacturers, you can visit their production factory. Here are some pictures about our customers visiting our workshop.

Visiting the manufacturer’s factory, you can know how they produce their automatic block making machine for sale, what brand of components they use, how their machine works and so on. You also can learn their equipment that produces the automatic brick equipment. Of course, you also can get a clearer idea of the strengths of your automatic brick machine manufacturer by visiting their factory or office.

In addition to that, you should ask them about the service they can provide. Good and timely service can help you solve your problems and reduce your loss to some extent.

To sum up, if you are interested in our fully automatic brick making machine, welcome to contact us and inquiry for its price! You also can continue to browse the website to learn more information about our company.